VIRTUAL CONSULTATIONS

Whilst things will undoubtedly be different this year, that doesn’t mean you can’t enjoy life’s

most luxurious pleasures. The enchantment still flows at Steven Stone.

The Stone way has always been to provide our clients with the utmost in bespoke service, which

is why we are offering 1-on-1 virtual consultations over the lockdown period.

Whether you’d like to talk about the diamond you have had your heart set or you want to discuss

an engagement ring you have seen on our website, we’re just one click away.

It could be something as simple as booking a repair in. Or detailing how the process works when

creating precious memories. Our experts are here to help whatever the occasion.

Your safety. Our priority.

The safety of our customers has always been our number one priority.

When we were allowed to open our doors and welcome clients back, we went above and beyond when

putting COVID safety measures in place.

And now we are giving you the chance to experience the Stone lore from home. We want to ensure

that every client gets the full Steven Stone experience, which is why our virtual consultations

are as close to a showroom experience as possible. Uncompromising, unrivalled service.

We know you may be wondering about the level of service a video consultation can deliver. It’s

only natural. But we’re here to assure you that our jewellers are trained to give the most

authentic experience to all of our clients. They are there to put you at ease and to make you

feel comfortable talking about any aspect of your jewellery desires - no matter the setting.

They will be at our showroom, able to take you round wherever you want to go. Once you begin

your video consultation, you will forget that you’re in your own home having immersed yourself

in the magic of diamonds. Our consultations are a special process and absolutely no expense has

been spared in bringing this enchantment directly to your home.

Superior matchmaking

Whether you want to treat yourself to the diamond you’ve always wanted or you’re after something

sentimental for your partner, our relaxed video consultations can match you to the perfect

piece.

It may be a completely handmade, bespoke commission or it may be a ready-to-wear ring. Whatever

it is, our consultations will ensure it is perfect down to the very last detail.

Or it may be as simple as a repair. You might just want to breathe new life into an old

heirloom. We can help you with that too. We pride ourselves on being authentic jewellers, not

resellers. If you need any jewellery assistance during lockdown, Steven Stone are always on hand

to deliver.

A Steven Stone Promise

We are committed to delivering an authentic experience, enveloping you in marvellous escapism.

Whether that be in our trademark showrooms or from the comfort of your own home.

It is a commitment that we take on with the utmost respect and is what sets Steven Stone apart

from the crowd.

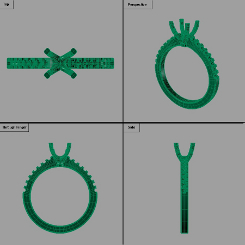

The next step is to stick the engagement ring along with other engagement rings onto a wax stem to create what is known as a "tree of wax". The wax tree is then placed into a can along with a mixture of investment powder and water which is poured over the tree and then place in an oven for 24 hours at a set temperature - know as the "lost wax process". Basically while the wax is in the oven it evaporates and the investment mix creates a mould around where the wax engagement rings and were. After 24 hours of being in the oven the can is taken out and placed into the casting machine where the metal - either 18 carat white and yellow or platinum is poured into the can and the moulds of the engagement rings . In the image below you can see what the engagement ring looks like after it has been casted into metal.

The next step is to stick the engagement ring along with other engagement rings onto a wax stem to create what is known as a "tree of wax". The wax tree is then placed into a can along with a mixture of investment powder and water which is poured over the tree and then place in an oven for 24 hours at a set temperature - know as the "lost wax process". Basically while the wax is in the oven it evaporates and the investment mix creates a mould around where the wax engagement rings and were. After 24 hours of being in the oven the can is taken out and placed into the casting machine where the metal - either 18 carat white and yellow or platinum is poured into the can and the moulds of the engagement rings . In the image below you can see what the engagement ring looks like after it has been casted into metal.  The next step is for the ring to be assembled and polished. Our skilled gold smith beautifully handcrafts each engagement ring by setting the diamonds, assembling the head of the ring and finally polishing the ring.

The next step is for the ring to be assembled and polished. Our skilled gold smith beautifully handcrafts each engagement ring by setting the diamonds, assembling the head of the ring and finally polishing the ring.